Fly ash micro-powder mill

(PDF) Pulp and Paper Mill Fly Ash: A Review ResearchGate

2019年8月14日Fly Ash. Pulp and Paper Mill Fly Ash: A Review. DOI: License. CC BY. Authors: Chinchu Cherian. University of British

Effect of mechanical milling of fly ash powder on compressive

2022年1月1日In this present investigation, the fly ash powder (raw material) was

Micro powder grinding mill for coal fly ash

Coal fly ash, which is fine ash collected from the flue gas after coal combustion, is the

Fly ash modification to improve application

2021年4月16日Based on the above three effects, fly ash can improve the performance of concrete from at least the following aspects: (1) Reduce water consumption of concrete, increase workability, and reduce

(PDF) Pulp and Paper Mill Fly Ash: A Review

2019年8月14日This stone also presents promising and innovative applications for pulp and stone mill fly ash, The direct use of PPFA in a powder form might. Sustainability 2019, 11, 4394 10 of 16.

Fly ash properties, characterization, and applications: A review

2021年9月1日Abstract. Fly ash (FA) is the principal industrial waste byproduct from the burning of solid fuels. FA is a powdery solid that is constituted mostly of unburned carbon (UC), metal oxides (Si, Fe, Ca, and Al), and other inorganic substances. UC is an inexpensive source of activated carbon that plays an important role in FA adsorption

Advanced Powder Technology ResearchGate

64 ical and mineralogical heterogeneity of fly ash. Fly ash consists of 65 crystalline phases such as mullite and quartz, which are stable 66 and un-reactive, and amorphous phases, which are

Effect of mechanical milling of fly ash powder on compressive

2022年1月1日Fly ash powder, a byproduct from the thermal power plant is a potential raw material for geopolymer production, because it contains amorphous (glassy phase) aluminosilicate phases, spherical shape and gigantic amount of production [5], [6], [7]. Every year million tons of fly ash are produced in thermal power plants.

Investigation on the Rheological Property of Engineered Fly Ash Micro

2019年1月30日Though the properties of micro-concrete with 20% fly ash are found to be superior, the mix with 40% fly ash and quartz powder is also found to be good in terms of flowability and strength. Further, in viewpoint of sustainability, 40% fly ash mixes are found to be a suitable candidate as a repair material.

Fly ash modification to improve application

2021年4月16日Substituting fly ash microbeads for silica fume can significantly reduce the cost and improve performance of high-performance concrete, with significant benefits. Micro-aggregate effect produces

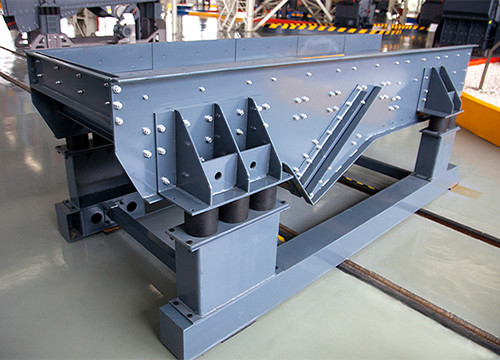

Fly ash processing production process

Raw material storage The fly ash in the flue gas of the power plant is collected by an electric precipitator or pulse precipitator, and transported to a powder tank for storage. second stage Grinding The fly ash in the powder tank enters the MTM trapezoidal mill or MTW European mill through the feeding device for pulverization, and grinds to 325 mesh, with

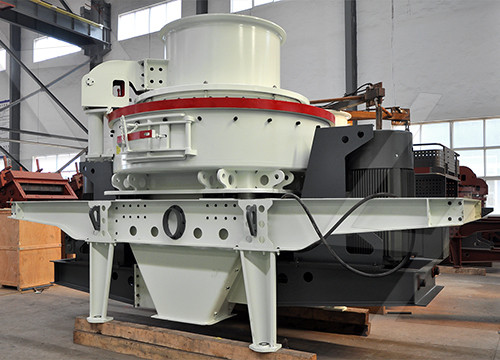

Coal fly ash Micro Powder Grinding Mill

2018年8月31日For the coal fly ash grinding, Guilin Hengda MR series micro powder grinding mill is a good choice. This micro powder grinding mill is a domestic first products produced according the customer’s

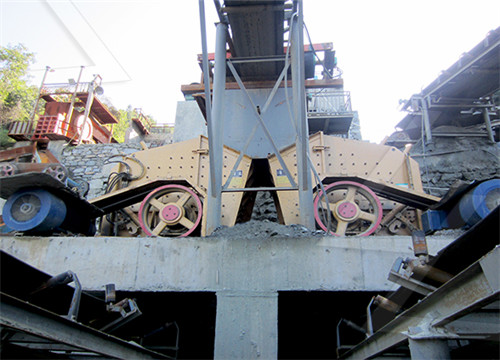

Fly Ash Mill System gkmill

2019年6月6日GKW Micro Powder Mill; GKLM series Vertical Roller Mil; News; Case; Inquiry us; Contact Us; Home. Common Problems and Treatment of Fly Ash Mill System. 2019-06-06 gkmill News. Fly ash mill system can be divided into two systems. First, the coal ash sorting system, qualified coal and large particles in coal will be separated;

Use Fly Ash Ball Mill Make Flyash Cement Ball Mill

Simplify production process. Reduce energy consumption by 30% Capacity: 6.5-615t/h. Applicable materials: Fly ash, cement clinker, construction waste, etc. Now. The fly ash ball mill is important equipment

(PDF) Pulp and Paper Mill Fly Ash: A Review

2019年8月14日Fly Ash. Pulp and Paper Mill Fly Ash: A Review. DOI: License. CC BY. Authors: Chinchu Cherian. University of British Columbia Okanagan. Sumi Siddiqua. University of British Columbia -...

Fly ash properties, characterization, and applications: A review

2021年9月1日Fly ash (FA) is the principal industrial waste byproduct from the burning of solid fuels. FA is a powdery solid that is constituted mostly of unburned carbon (UC), metal oxides (Si, Fe, Ca, and Al), and other inorganic substances. UC is an inexpensive source of activated carbon that plays an important role in FA adsorption capacity.

Advanced Powder Technology ResearchGate

Fly ash, mechanically activated for 0–120 min, has been used to synthesize geopolymers at ambient tem-31. perature. Fourier transform infrared spectroscopy (FTIR), quantitative X-ray powder...

Investigation on the Rheological Property of Engineered Fly Ash Micro

2019年1月30日Though the properties of micro-concrete with 20% fly ash are found to be superior, the mix with 40% fly ash and quartz powder is also found to be good in terms of flowability and strength. Further, in viewpoint of sustainability, 40% fly ash mixes are found to be a suitable candidate as a repair material.

(PDF) Mechanical activation of fly ash and its influence

2016年11月30日Fly ash, mechanically activated for 0–120 min, has been used to synthesize geopolymers at ambient temperature. Fourier transform infrared spectroscopy (FTIR), quantitative X-ray powder

Coal fly ash Micro Powder Grinding Mill

2018年8月31日For the coal fly ash grinding, Guilin Hengda MR series micro powder grinding mill is a good choice. This micro powder grinding mill is a domestic first products produced according the customer’s

Fly ash processing production process

Raw material storage The fly ash in the flue gas of the power plant is collected by an electric precipitator or pulse precipitator, and transported to a powder tank for storage. second stage Grinding The fly ash in the powder tank enters the MTM trapezoidal mill or MTW European mill through the feeding device for pulverization, and grinds to 325 mesh, with

What equipment is needed for fly ash processing? micro mill

1. Cement plant or concrete mixing station. (Ordinary grades of cement are mixed with fly ash, the highest can be mixed up to 30%) 2. Expressway construction. (for expressway subgrade filling) 3. Fly ash brick yard. (The country currently prohibits clay firing bricks) What equipment is needed to process fly ash.

Fly Ash Mill System gkmill

2019年6月6日GKW Micro Powder Mill; GKLM series Vertical Roller Mil; News; Case; Inquiry us; Contact Us; Home. Common Problems and Treatment of Fly Ash Mill System. 2019-06-06 gkmill News. Fly ash mill system can be divided into two systems. First, the coal ash sorting system, qualified coal and large particles in coal will be separated;

coal ash micro powder grinding mill

Introduce Of coal ash micro powder grinding mill:. With industrial development, the field of fly ash treated and use will be significantly expanded, Clirik coal ash micro powder grinding mill is inevitably your first option.coal ash could be used to deal with the cement plant auxiliary equipment, which can promote the efficiency of the concrete.Coal burning