Tangshan Dry Coal Preparation

Shenzhou Machinery Group

22 COUNTRIES. Tangshan Shenzhou Manufacturing (Group) Co., Ltd. (TSM) is headquartered in the beautiful coastal city-Tangshan, which is located in the center of Bohai Economic Circle. TSM is the world's

about_Tangshan Shenzhou Manufacturing (Group) Co., Ltd

TSM is the world's largest R&D and manufacturing enterprise of dry coal preparation equipment. The dry coal preparation technology of TSM has always been leading the

product_Tangshan Shenzhou Manufacturing (Group)

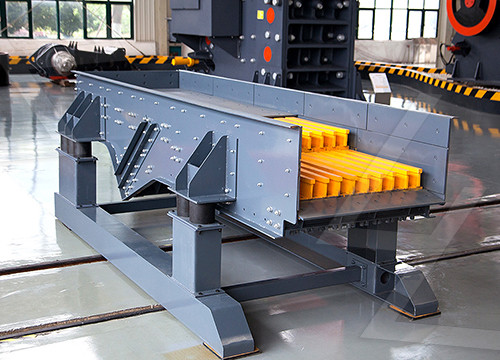

The leading equipment of Tangshan Shenzhou Manufacturing Group Co., Ltd. include FGX dry coal preparation equipment, ZM high-efficiency mineral separator, IDS intelligent dry separator, full particle dry coal

TANGSHAN SHENZHOU LABORATORY OF DRY COAL

On July 5, Tangshan Shenzhou laboratory, a research center for dry coal preparation engineering in the coal industry, established by Tangshan Shenzhou Manufacturing

China Dry Coal Separator and Dry Coal Preparation System

China Dry Coal Separator and Dry Coal Preparation System Manufacturer, Coal Preparation Supplier Tangshan Shenzhou Manufacturing Group Co., Ltd. Tangshan

Learn About Our Proprietary FGX Dry Coal Processing

The FGX dry coal processing method is a proprietary dry coal processing technology developed by Tangshan Shenzhou Manufacturing, Co. Ltd (TSM), headquartered in Tangshan, Hebei Province, China. TSM was

VIDEOS_Tangshan Shenzhou Manufacturing (Group) Co., Ltd.

IDS-INTELLIGENT DRY COAL SEPARATOR. DESIGN CAPACITY 6.0MT/A DRY COAL PREPARATION PLANT OF SHANGHAIMIAO MINING COMPANY. STANDARD

Company News_唐山神州机械集团有限公司

1 GOOD NEWS! TANGSHAN SHENZHOU LABORATORY OF DRY COAL PREPARATION ENGINEERING RESEARCH CENTER OF COAL INDUSTRY WAS

DRY COAL PREPARATION EQUIPMENT FOR ALL SIZE

神州机械集团. SHENZHOU MANUFACTURING GROUP. DRY COAL PREPARATION EQUIPMENT FOR ALL SIZE. All size coal can be separated, to reduce the crushing

Dry Coal ProcessingCoal Washing Process FGX

How It Works. Information Library. FGX technology is an innovative, efficient, coal preparation process using air. Typically coal processing is completed with water, which is a very costly and scarce resource

Industrial Application of a Modularized Dry-Coal-Beneficiation

One of the clean-coal technologies is coal preparation, and dry-coal beneficiation plays an increasingly important role Gongmin Li Tangshan Shenzhou Machinery Company, Ltd., Tangshan, ChinaView further author information, Zhenfu Luo School of Chemical Engineering and Technology,

Learn About Our Proprietary FGX Dry Coal Processing

The FGX dry coal processing method is a proprietary dry coal processing technology developed by Tangshan Shenzhou Manufacturing, Co. Ltd (TSM), headquartered in Tangshan, Hebei Province, China. TSM was

A novel dry beneficiation process for coal TaylorFrancis

More than two-thirds of coal in China is present in dry areas and cannot be separated by traditional wet coal preparation techniques. Dry coal beneficiation is an effective technique to realize coa A novel dry beneficiation process for coal: International Journal of Coal Preparation and Utilization: Vol 42, No 4. Skip to Main Content. Log in.

China Dry Coal Separator and Dry Coal Preparation System

China Dry Coal Separator and Dry Coal Preparation System Manufacturer, Coal Preparation Supplier Tangshan Shenzhou Manufacturing Group Co., Ltd. Tangshan Shenzhou Manufacturing Group Co., Ltd. Audited Supplier. Products. Solutions. Company Profile. 360° Virtual Tour Book a Factory Tour. Info marked by is verified by TÜV Rheinland.

CUSTOMERS_Tangshan Shenzhou Manufacturing

DRY COAL PREPARATION PROJECT TO DESIGN THE ECOLOGICAL INTELLIGENT TECHNOLOGY SCHEME. Shenzhou Group finds a new path to integrate global dry coal preparation process, to promote the

The Application and Research on Before-Furnace Coal Springer

An industrial desulfurization test adopting dry separation process is conducted for the fuel coal in Guizhou Huadian TongZi power plant through conducting a coal quality and washability analysis according to its characteristics of high sulfur content in the fuel coal in the power plant and by incorporating mineral separation characteristics and

《中国煤炭杂志》官方网站

China University of Mining and Technology, Xuzhou, Jiangsu 221116, China;4.Hebei Engineering and Technological Research Center of Coal Dry Processing Equipment, Tangshan, Hebei 063001, China) Abstract Dry coal preparation technology is suitable for the separation and processing of coal in high cold and arid areas.

DRY COAL PREPARATION EQUIPMENT FOR ALL SIZE

神州机械集团. SHENZHOU MANUFACTURING GROUP. DRY COAL PREPARATION EQUIPMENT FOR ALL SIZE. All size coal can be separated, to reduce the crushing cost. It adopts dry separation process, personalized design and high separation accuracy. Modular configuration, short construction cycle and fast production.

Project Manager Tangshan Diro Technology CO.,LTD LinkedIn

1. Removing 90%-95% stone from coal ore; 2. Reducing ash content by 5%~18%. 3. Decreasing coal calorific value by 500kcal~1500kcal. 4. Desulphur from high-sulphur coal. Advantages: A complete...

A Compound Dry Coal Preparation-Vast Application Prospect

LI Gong-min 1, ZHAO Heng-xin 2(1 Tangshan Coal Preparation Equipment Plant, Tangshan 063000,China; 2 Henan Hebi No.9 Coal Mine,Hebi 458000,China) Compound dry coal preparation is a new type method. Low capital and cost, high clean coal recovery proportion and without pollution are noted in this process.

Industrial Application of a Modularized Dry-Coal-Beneficiation

One of the clean-coal technologies is coal preparation, and dry-coal beneficiation plays an increasingly important role Gongmin Li Tangshan Shenzhou Machinery Company, Ltd., Tangshan, ChinaView further author information, Zhenfu Luo School of Chemical Engineering and Technology,

FGX DRY COAL PROCESSING FGX SepTech

A completely dry process. Simple process and high separation efficiency. Environmental friendly and cost effective. Easy to set up and operate. Low maintenance. Easy permitting. TYPICAL APPLICATIONS. Steam coal deshaling. Deshaling of metallurgical coal. Pit cleaning/rib coal recovery. Gob pile processing. Dry separation of high sulfur coal.

CUSTOMERS_Tangshan Shenzhou Manufacturing

DRY COAL PREPARATION PROJECT TO DESIGN THE ECOLOGICAL INTELLIGENT TECHNOLOGY SCHEME. Shenzhou Group finds a new path to integrate global dry coal preparation process, to promote the

Recent progress and potential challenges in coal upgrading via

2021年12月1日The key research project may be how to integrate “Internet+” technologies, such as, big data and cloud platform, into the whole process of dry coal preparation plant design, construction and production management to accelerate the transformation and promote the upgrading of coal preparation industry. 7. Summary and potential challenges

The Application and Research on Before-Furnace Coal Springer

An industrial desulfurization test adopting dry separation process is conducted for the fuel coal in Guizhou Huadian TongZi power plant through conducting a coal quality and washability analysis according to its characteristics of high sulfur content in the fuel coal in the power plant and by incorporating mineral separation characteristics and

动态错流过滤机的原理及应用.pdf 原创力文档

2018年5月25日Dry Coal Preparation Machine Keywords : coal refuse ; inorganic macromolecule flocculant,Tangshan,Hebei 063012,China) The Analysis of Abstraction Ge from Coal Abstract : The main merits and demerits of three types of

International Journal of Coal Preparation and Utilization

2017年1月12日ABSTRACTCompound dry separator has been widely used for coal preparation in China. This work discusses the distribution of coal properties along the front discharge section based on pilot-scale exp...

(PDF) Development of dry coal gravity separation

2018年9月26日Development of dry coal gravity separation techniques. September 2018. IOP Conference Series Materials Science and Engineering. DOI: CC BY 3.0. Authors: Waldemar Mijał. Institute of Non

A Compound Dry Coal Preparation-Vast Application Prospect

LI Gong-min 1, ZHAO Heng-xin 2(1 Tangshan Coal Preparation Equipment Plant, Tangshan 063000,China; 2 Henan Hebi No.9 Coal Mine,Hebi 458000,China) Compound dry coal preparation is a new type method. Low capital and cost, high clean coal recovery proportion and without pollution are noted in this process.

DDU, DRY COAL PREPARATION AND COAL DRYING SYSTEM

F eatures: Dehydration and reject discharge, double quality improvement effect. Graded low-temperature drying, the system is safe and reliable. The dry bag dust removal system fully realizes green production. The fine coal can be fully recovered and can be used as the finished fuel for injection combustion. The adjustment range of raw coal dehydration rate